An Aggressive Timeline

Our best-case, wildly optimistic timeline went something like this: secure a builder in November, finalize design in December, submit permits the week before Christmas, work through a round or two of county Q&A, then receive approval sometime in mid- to late January. A perfect plan—what could possibly go wrong?

Reality, as it turns out, had other plans. Better ones.

Steps one and two went almost according to plan. We secured the builder only in December—about a month later than expected—which pushed final design. Still, we managed to get everything filed more than a full week before Christmas. Then, predictably, everyone went on break. Well… maybe just us and our builder. Montgomery County, it turns out, went straight to work.

While en route to visit my dad and brother in Pittsburgh on the 26th, halfway along the Pennsylvania Turnpike—white-knuckle driving under ideal conditions—we were racing west toward the Oakmont Bakery to pick up my annual haul of pies and brownies for dad’s post-Christmas gathering when the dashboard lit up with an email notification from Montgomery County Department of Permitting Services.

Not exactly the moment I expected to hear back, I thought, as I swerved the Explorer through the infamous S-curves.

We’d been told by just about everyone that Montgomery County DPS was refreshingly human: organized, approachable, and far less adversarial than neighboring jurisdictions in Washington and Northern Virginia. Several people suggested an upfront meeting with the review team—get aligned early, understand expectations, avoid surprises. Sensible advice. We followed it.

Armed with that guidance—and more than a little help from ChatGPT to navigate the maze of documentation—we took our shot the week before Christmas. Plans uploaded. Forms submitted. A small forest saved by PDF uploads. Then… silence.

Approval

Storming towards the Allegheny Tunnel, snow, fog, and wind blowing like crazy, we had to know the verdict. Fishing my phone out of my pocket—and if my nieces and nephews are reading this, don’t do that—tires slicing tracks in the fresh mountain snow, I activated Face ID to log in.

And the result?

Approval pending final payment of the application fee. Nothing else. Everyone’s advice was right.

We were a “go” for the remodel.

Needless to say we were armed not just with cherry pie but also in high spirits when we finally arrived. And it’s a good thing we had a chance to relax a few days at my dad’s and brother’s houses, because we were about to return to a whirlwind of activity when we returned to Washington.

Precision Elevated

Fastidious?

Fastidious isn’t a word I use lightly—or, if I’m being honest, at all—but it’s the only one that truly fits our contractor.

With a background as a PwC auditor, he approaches renovation with near-surgical precision. You know the saying: measure twice, cut once. Between the builder, his partner, and—naturally—Ramiro and I, it became something closer to measure 200 times, cut once… then measure again in case someone blinked.

And yes, it sounds like overkill. Until you remember that the very spot we were quadruple-checking down to the millimeter is where a 26-foot steel beam would serve as the structural backbone of the first-floor redesign. Its landing point—right in the middle of the house—would also, cement (so to speak), the final location of the refrigerator and pantry.

At that location, the beam transfers its load into a steel post designed to carry both the 600-pound beam and 84,000 pounds of house above it. The engineer cared deeply about load paths, tolerances, and even details like average annual snowfall sitting on the roof. We cared about design and usability. Our builder was sweating both.

To add to the pressure, the structural engineer required the beam to shift forward by a foot from the original wall line, shrinking the cantilevered portion to meet today’s code. He also flagged that second-floor walls had been built over the cantilever—likely an error by the original builder. His ruling had already moved the refrigerator once in our kitchen design. We really didn’t want it to turn into a double play.

Somewhere between refrigerator depth vs. pantry and structural soundness vs. sinking house, a mere dot on our architectural diagrams turned into a full-blown game of measurement Tetris. And so the tapes came out.

Which is how we ended up measuring the kitchen so many times the tape measures should’ve earned retirement packages.

Our Giant Dirty Hole

No Post Like the Present

Eventually, the measuring had to stop and the digging had to begin.

After dozens—and I mean dozens—of “final” steel post positions, we collectively picked a spot, nodded with conviction, and committed. The crew arrived and carved a 4-foot square hole smack in the middle of the house, which—once filled with rebar and concrete—would serve as the footing for the steel post.

No pressure.

With the floor opened up and the framing temporarily peeled back, the hole did something unexpected: it offered a glimpse of the future. What had been a sad little pantry—just 20 inches wide and 12 inches deep, barely enough for our Italian seasonings, let alone a plethora of professional-grade appliances—was suddenly reimagined. In its place would be a 5-by-7 foot pantry, with a five-foot coat closet on the opposite side. There is even a small nook to mount our cordless vacuum.

It was one of those rare renovation moments where destruction clarified intent. The mess wasn’t chaos anymore, to us—it was proof that the plan was unfolding. Sometimes I guess you just need a large, dirty hole to see where you can put things.

aLL MeaSuriNg anD nO PosT maKeS ToDd a duLL BoY

The Post of No Return

No time was lost between permit approval and steel beam installation. From that moment on the Turnpike to the instant we spray-painted a fateful orange dot onto the fresh concrete—marking the final location of the steel post, and yes, measuring one last time—barely three weeks had passed.

And then the day arrived.

I didn’t sleep at all the night before. I kept waking, replaying the sequence ahead, worrying about everything that could go wrong. Which made no sense—I wasn’t lifting the beam myself. Two very large machines would handle that. Still, my sleep was interrupted by stress dreams featuring measuring tapes, refrigerators jutting out too far from cabinets, and the lingering fear that we’d somehow mismeasured the one thing that mattered.

Once steel shows up, there’s no undo button.

Today is Beam Day!

Machines Lifting the Beam In Place

Decisions Become Deadlines

“I think our builder is moving too fast,” says almost no one. Ever.

And yet, here we were. With the steel beam hoisted into place, framing was next—and suddenly Ramiro and I were the bottleneck. To keep momentum, the house needed stuff, and lots of it. Plumbing rough-ins for three bathrooms, electrical layouts for final build, lighting plans, tile selections, grout color, fixtures, hardware. All of it. Now.

All eyes were on us.

Anyone who knows me will appreciate how shocking this was: we weren’t shopping fast enough! Yes, we had chosen finishes—what felt like years ago, but was actually about a month prior. Choosing, it turns out, is the easy part. Ordering requires math, never my strongest suit.

Exact wall dimensions for the kitchen—what walls would actually remain. Total square footage for tile and flooring. Confirming which showers worked with which valves. Verifying clearances. Re-checking lead times. Multiply that by three bathrooms and eight rooms, and suddenly our time on weekends became the constraint.

A Thousand Points of Light (Switches)

That reality hit hardest when the conversation turned to lighting.

“Where do you want the light switches?” our electrician asked, pausing.

To which I replied, “What light switches?”

The ones that were in the walls we just took down. They’re dangling over there,” he replied, pointing.

And just like that, it clicked: tearing down interior walls doesn’t just open space—it resets the logic of the house. Lights that were once perfectly centered between walls suddenly weren’t in the open spaces. Fixtures were off by several inches. Switches, still dangling in midair, needed new homes.

To keep plumbing and electrical moving, we spent an entire weekend finalizing hardware and marking walls and ceilings with red wax pencils, mapping lighting like a forensic investigation.

And maybe we overdid it—but true to midcentury form, we took a lawyered approach to the lighting. Tall wall sconces—they look like we stole them from the Empire State Building—will flank floor-to-ceiling windows in the living and dining rooms. The dining room adds a midcentury masterpiece chandelier and four recessed spotlights. The kitchen lighting adds several more layers: recessed spots, four pendants over the island, task lighting at the sink, under-cabinet lighting—all on dimmers, all intentional for the period.

Which meant every fixture had to be placed precisely. Marked in real space. On real walls. On real ceilings, or where ceilings would eventually be.

Beam Up … Switches Down

The Baby Beam

The steel beam wasn’t the only structural star of the show. Its quieter sibling—a wood beam opening up the first-floor primary—was installed a week earlier.

With the pony walls removed, the room stopped behaving like two adjacent spaces and started acting like one. Sightlines opened up, circulation improved, and what had once felt divided now feels deliberate. A unifying structural move that makes the space work for us now and into the future.

First Floor Primary Opened Up

Final Decisions

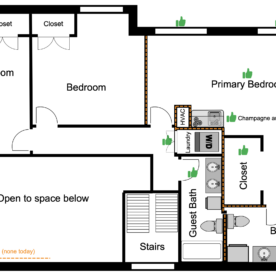

With just one weekend left before framing complete, we were down to the final calls—the kind that don’t feel dramatic until you realize they’re permanent. Two decisions remained unresolved: the size and layout of the downstairs bathroom, and the fate of the fireplace.

Moving the HVAC to the attic opened up an entirely new set of possibilities for the first-floor primary. A larger shower? Absolutely. A full reconfiguration with double sinks? Tempting—if we were willing to sacrifice the coat closet and eliminate the Jack-and-Jill entry. Not to mention pony up more cash.

In the end, practicality won. That space will function primarily as a powder room, a full bath only occasionally as overflow when the upstairs guest bedrooms are full. Also, it was important to us to keep both entry points, that Jack and Jill concept was very popular in midcentury design. So we split the footprint between a larger shower and a dedicated shoe closet. Easily accessible to guests, and, yay, more shoes!

The fireplace decision was easier.

Once we realized the wood surround wasn’t original—and leaned far too orange for the future wood tones of the kitchen and pantry—the verdict was swift. Out came the jackhammer. In the place of protruding brick will be a bold black-and-white geometric surround and flush-with-floor hearth. Black and white geometric tile will reimagine a midcentury take on a classic that’s become a personal signature of mine.

Like my Sydney house, sometimes “final decisions” aren’t about adding more. They’re about knowing exactly what to remove.

Jack Hammering Out the Fireplace

What’s Next – Chapter 8

Next comes Chapter 8—the first renovation Ramiro and I tackled together. It’s where I graduated from cosmetic fixes to real structural change, learning that good design isn’t just about how a space looks, but how it works.

We took on a full master bathroom reconfiguration, a whole-floor remodel to create a proper movie theater, and my first modern black-and-white floor in the kitchen—a move that quietly set the tone for everything that followed. It was equal parts ambition, education, and trust, and it changed how we approach renovation to this day.